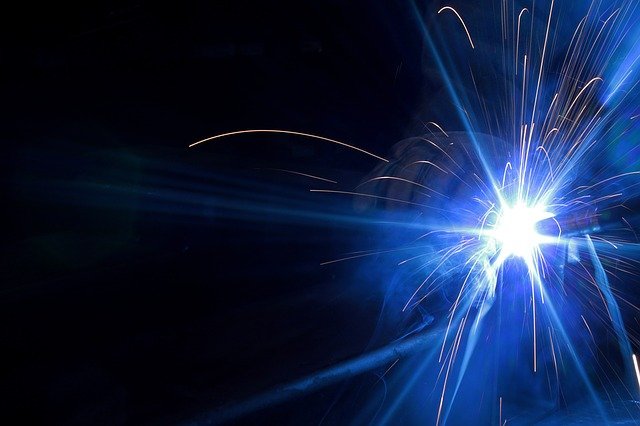

Welding with the TIG 141 method is very popular and extremely universal. It is based on the use of a non-consumable tungsten electrode in a shield of inert gases such as argon, helium or their mixtures. However, it is worth remembering that nitrogen cannot be used in this case. This method can be used for both automatic and manual welding. It is suitable for welding all types of steel with direct current. It is also used when joining aluminum and aluminum alloys using alternating current. It allows you to get really high-quality welded joints.

It is worth starting with the fact that when welding with a tungsten electrode, the arc glows between a non-consumable electrode made of pure tungsten or tungsten refined with oxides (thorium oxide (IV), zirconium (IV) oxide, lanthanum (III) oxide and others) and the welded material. The tungsten electrode is most often connected to the negative pole and the ground terminal to the positive pole. As a result, more heat is generated at the point where the weld is formed and less stress is placed on the tungsten electrode.

Stainless steel is a material that is used primarily where high resistance to rust is required. It is therefore used in many different industries. We most often use it to make table bases and cleats. We weld stainless steel using the TIG method, which allows us to weld elements whose thickness is from tenths of a millimeter to even several hundred millimeters.